LEAN Optimisation for Office Work – Waste of time or gamechanger?

LEAN and the Toyota Production System – Outside the factory floor.

My intention for this article is to give an introduction to the world of LEAN and describe more specifically how LEAN thinking processes, developed for the world of manufacturing, can be applied to a setting like sales or office-work.

When first introduced into LEAN, Six-Sigma and other similar tools in the past, I always struggled to find applicability to my role. Often these types of initiatives are seen as another corporate fad which comes and goes. Recently, however, I have been involved in several LEAN optimisation projects and I have started to understand the true benefit of this set of methodologies. Instead of manufacturing, we are applying LEAN in what can be thought of as “knowledge factories”. A knowledge factory is a business or team where people contribute knowledge to the “product” as it passes through a process. The primary output is knowledge-based. In my case, my team is a knowledge factory which produces proposals and sales contracts.

The LEAN toolset has helped us take a structured approach to tackle wide-ranging problems faced within the business. We are on a path to reducing defects in our work, streamlining communications and improving our bidding cycle time. This will eventually make us more competitive and improve employee satisfaction too.

The details and tools described below are just a glimpse into the world of LEAN. I learned how to apply these methods to my organisation from a LEAN coach. If you have such people in your organisation, seek them out. Alternatively, there are plenty of resources and training available online.

What is LEAN?

LEAN is a set of business optimisation principles derived from the study of the Toyota Production System, which was first introduced in Japan in the 1950s. The drive for kaizen (continuous improvement) came about in response to Japan’s need to compete in the world following World War II. The Japanese people were required to do this in an environment of limited space and resources. Being faced with such constraints, they developed an innovative set of processes to reduce waste, implement ‘just-in-time’ delivery and improve quality. These principles helped the Japanese people become global leaders in manufacturing and technology.

Many of the terms used in LEAN are Japanese and so can seem unfamiliar but don’t let this put you off, focus on the underlying concepts which are described below.

Kaizen

Kai (Change) Zen (To make it better)

To understand the concept of kaizen think of the proverb: “Give a man a fish and you feed him for a day; teach a man to fish and you feed him for a lifetime”

One of the core principles of LEAN is that, to implement change in your organisation, you should only provide 50% of the solution and then let the team get their hands dirty. This encourages involvement and motivation and is more likely to achieve long term impacts.

The key focus areas of Kaizen are:

- Identifying and eliminating unnecessary waste

- Reducing costs

- Eliminating defects

- Improving quality

Look for a key internal issue facing your business and arrange a kaizen workout with the personnel (“operators”) directly involved in the process.

Here are some questions which can be used to initiate the discussions:

- Can a piece of work or process be carried out with half the people or in half the time?

- Sales teams add value by listening to customers, how can you streamline your internal processes to help sales engage with more customers?

- In the office, can you implement more efficient document control and sharing? Could you reduce the number of copies of data or time spent locating data? Can you go paperless?

In all business processes, the “operators” are the stars. Operators are the people who are performing the work. The focus needs to be on them, not the managers or supervisors. Operators add value at each step of the process, managers are there to help and empower the operators. This is why the operators need to be at the heart of any kaizen workout. If you want to sustain change, you need to involve the operators in the improvements. This will encourage acceptance and ensure that changes are implemented in the most practical and useful manner.

Additionally, the team need to be working towards making changes which can’t be undone, otherwise, people tend to move back to their old ways.

Tools and Methodologies

Below are the main tools that I have found most useful to apply LEAN in my business. They can be used individually or together as appropriate for your specific case.

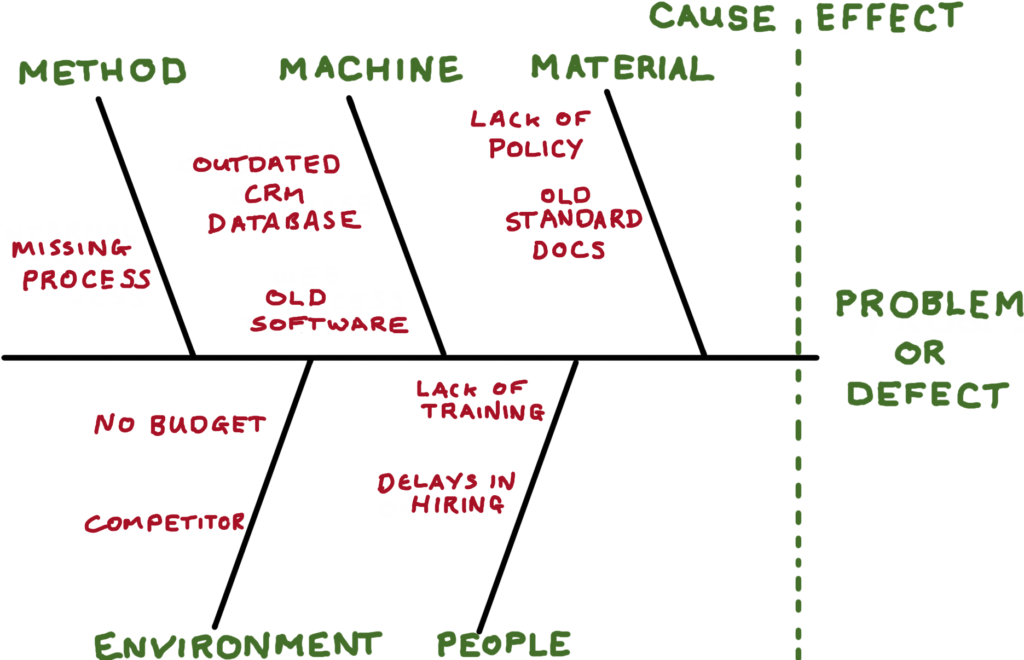

1. Personnel, Machine, Material, Method and Environment – Cause and Effect

To start addressing any problem or defect within your organisation, you need to start by understanding the issue and its relationship to Man (People), Machine, Material, Method and Environment sometimes known as 4M+E.

Start by drawing what is known as a fishbone diagram with the problem or defect at the head. Then, in collaboration with your team, start to populate the branches under each of the 5 categories with the underlying causes of the problem. The figure below is intended to give you some ideas on how to get started.

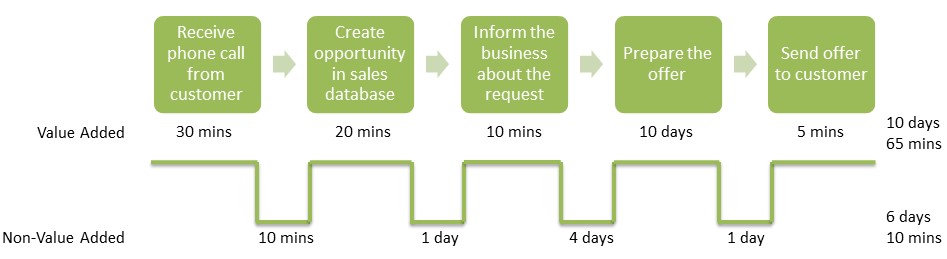

2. Value stream mapping (VSM) – Eliminating Waste

A value stream map is a representation of material and information flow through any process. VSM is particularly helpful at identifying sources of waste or waiting time in your business processes. This visual flow chart is a good way to start analysing the system and making improvements. Start with a ‘current state’ chart, look for areas where there is waste or delays and then adjust the ‘future state’ VSM to address them.

The best people to help design an improvement to a specific process are the operators who are using it. Speak with the workers to find out what they are actually doing at each step. Seek real situations and examples and keep questioning why a methodology is used. Physically go to where the work is happening and observe with your own eyes. See what the employees are experiencing. Sit with them in the office, ask to see the tool or document they are using and join the meetings. This enlightening process will give you insight into unseen areas of your business and will help to generate ideas for improvement.

3. The 5 S’s

Once you have a ‘current state’ value stream map of your process flow, you can now start to apply the 5 S’s.

- Sorting Out

- Sort out what is needed and what isn’t.

- Where can you remove unnecessary or non-value added steps?

- Set in Order

- Align the process into discrete blocks of “standard work”, paying attention to the sequence of steps and who does what. (See the standard work section and swim lanes tool below)

- Shine

- Clean and inspect the environment.

- Apply this to document repositories, employee policies or instructions.

- Standardize

- Set the standard to maintain.

- Do all your employees know and understand the standard work packages to achieve a successful outcome?

- Sustain

- Make sure the standards are met.

- Introduce training and KPIs (Key Performance Indicators) for the team to ensure the changes are maintained.

4. Standard Work

Standard work is the practice of setting, communicating, following, and improving standards. Establishing standard work begins with creating, clarifying, and sharing information about the most efficient way to perform a task that is currently known amongst those carrying it out. For more details on this check out this blog.

Surprisingly, standard work is critical in knowledge factories and this is often the place in which it is most lacking. This is because most knowledge work exists in people’s heads and is based upon their experience. It is, therefore, often not formally written down. Without standard work, there is often no concrete way to assess what normal and what is abnormal.

Keep in mind that standard work needs to change and adapt with changes in people, process and materials: it should not be a static quantity. You can use Kaizen to implement changes in standard work.

Question: Do you have clear examples of standard work in your office? Can anyone step in to complete a process or task, based upon the well defined standard work?

For example, you could define a “standard work” for: How to be more efficient in meetings and limit them to 30 mins. The meeting facilitator will send a clear agenda and meeting invite, 24-48 hours before the meeting so that each participant can prepare their contribution in advance. Each participant is given the opportunity to present their input in 30 seconds and the remaining meeting time can then be used to make a decision.

5. Fixing Defects

Golden Rule of LEAN: “Don’t accept a defect and don’t pass on a defect.”

It is very important to re-enforce your quality checks during the preparation of a piece of work to stop defects earlier in the process. Having your quality review at the end, which is the most common implementation in knowledge work, is too late. This will inherently lead to lost time and re-work which causes delay and frustrates the operators.

It is critical that your employees take responsibility for the quality of their work. Ask yourself, how can you take inspectors, approvals or auditors out of the workplace and instead have the operators self-perform the checks?

If someone is handed a defect and then fixes it, the team will never be forced to address the issue that generated the defect. You should always try to send a defect back to the operator who generated it.

One method to control this is to use a simple pass-or-fail test at each step. Can you create a checklist for each operator to validate the work before handover?

An example from Toyota is on the manufacturing lines where they have hundreds of operators. At each stage of manufacturing the operator has their own quality checks built-in to their work. As a result, they don’t need to have a final inspection of the vehicle and it comes out of the line ready to ship to the customer.

Question: Can you remove the inspectors or approvers from your process and build in quality?

6. Poka-yoke

Poka-yoke means “to error-proof” so mistakes can be avoided. Does your process include fail-safe mechanisms so that your operators are prevented from failing or causing a defect?

A few examples of this are:

- A game-boy cartridge, where even a 3-year old child can figure out how to insert it because it only goes in one way.

- The starting interlock on your car. This prevents you from start the engine unless your foot is on the brake.

Question: How can you apply this concept of error proofing to your process? Can you potentially amend your IT tools to include error checking or introduce checklists?

7. Single Piece Flow

The process flow is another important area of optimisation. The aim is to make sure that work is not obstructed as it passes from one person or step to another. Ask yourself how can you can make only what is needed downstream and ensure it is ready just in time. Through the elimination of wasteful work and by connecting or flowing processes together defects will also be spotted more easily.

Single piece flow aims to ensure that your employees only work on one task at a time. Multi-tasking is proven to cause inefficiency, so don’t build it into your process. Furthermore, multiple handoffs in the process should be avoided. Each time a piece of work is handed off between operators or departments it causes opportunities for waiting time, delay and defects due to miscommunication.

This issue of handoffs for knowledge-based works is particularly insidious because handoffs are often invisible to the process owners, or even the management teams, but are a significant source of defects.

To address this problem you can use a swim-lane chart to visualise the process:

To generate a swim-lane gantt chart, write a task list for each step of your process. Identify who each task is assigned to, the duration of each step and the predecessor task or tasks. You can then use a simple gantt chart tool to display this information.

Now you should have a visual representation of the process and all the handoffs. Can you now optimise the process to reduce handoffs and give each operator one task at a time? Start playing with the flow and optimise a future state version.

Conclusion

LEAN thinking has just as much application to knowledge-based work as it does to a factory. Use kaizen to make sure your people can be successful at performing their standard work in the right way. If you optimise your processes, it will create clarity, reduce stress and remove waste. This will ultimately result in better outcomes and happier employees.

Remember: Ideas → Try → Kaizen.

Best of luck on your LEAN journey and let me know how you progress by commenting below or sending me a message.